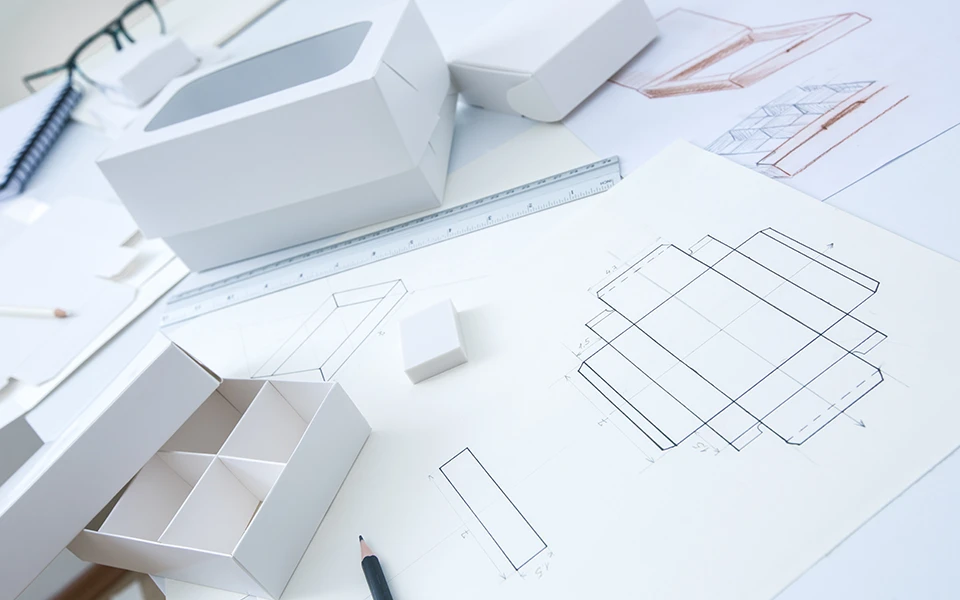

Structural design

Our structural design team challenges our customers to think about traditional packaging in new ways.

The goal is to design and create innovative solutions using in-depth knowledge of carton engineering with state-of-the-art computerized design software.

A prototype sample allows for testing for fit, form and function.